Blower manufacturing competence

Extensive know-how

Experts – from the designer through to the machine manufacturer and right up to the electrical engineer – create an unbeatable team.

Using state-of-the-art software, hardware and measurement technology, and in close interaction with universities and non-university research institutions, this team allows us to set new limits every day.

Participation in joint industrial research with:

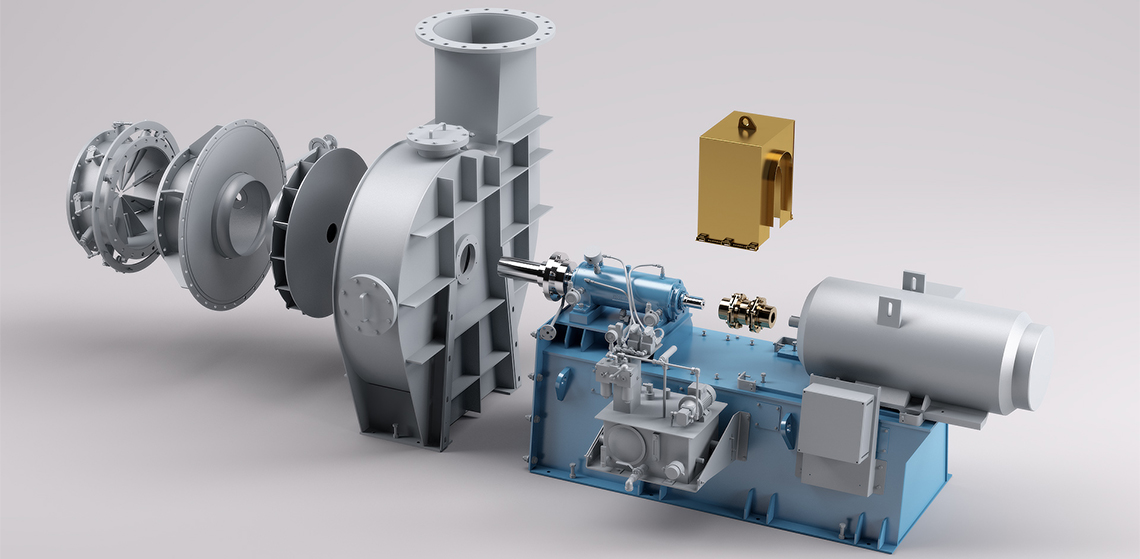

Centrifugal Blowers – Made by PILLER

Unparalleled manufacturing competence

We offer high-level expertise in the sectors of the process industry. Skills in welding, the selection of material/coating and our R&D make us a preferred manufacturer for blowers & compressors.

Manufacturing excellence: Welding

PILLER stands for the highest level of manufacturer qualification in welding. Whether E Hand/arc, TIG, MIG or MAG: In the metalworking sector, our welding specialists can weld almost everything possible.

At PILLER, welding technology and especially the quality of a weld, is given the highest priority.

We meet the requirements stipulated in the Pressure Equipment Directive 2014/68/EU and have a manufacturer qualification according to AD 2000 (Data Sheet HP0) and the quality requirements for welding manufacturing plants according to DIN EN ISO 3834-2 and DIN 2303.

Welder's Qualification Test

In addition, we have extensive welding qualification certificates compliant with DIN EN 287/DIN EN ISO 9606 and our welding processes are approved according to DIN EN ISO 15614 for the processes MAG 135, WIG 141 and E Hand 111, for non-alloy and low-alloy steels, high-alloy corrosion-resistant CrNi steels, austenitic-ferritic, duplex and super-duplex steels and titanium. All welded joints are made based on the DIN EN ISO 9606 standard.

Weld Seams

All welds are tested using the following procedures by qualified and certified inspection personnel according to DIN EN ISO 9712, Level II and III, depending on requirements and customer specifications:

- VT visual inspection

- PT penetrant test

- MT magnetic particle examination

- UT ultrasonic test

- RT X-ray test

MADE BY PILLER – A seal of quality

PILLER stands for strong quality management. Comprehensive quality assurance tests as well as organizational measures of quality management always guarantee high product quality.

High-power blowers and compressors with the "MADE BY PILLER" seal of quality are in great demand all over the world. PILLER ensures the highest quality and operational reliability of all its products and services. Our quality is based on comprehensive quality assurance and a quality management system according to DIN EN ISO 9001. Furthermore, PILLER has numerous approvals and manufacturer qualifications such as the approval for the welding of military installations according to DIN 2303 Q2 BK2, approval as a welding company according to DIN EN 3834-2 and AD2000 HP0, as well as approval compliant with EAC TR CU.

Reliable blower quality

Our processes are subject to dynamic, cutting-edge control loop. The organization consistently complies with legislative requirements and standards, and implements them reliably. The goal of all methodologies used is the preservation and development of our product quality and related services – starting from central standardization and documentation control, through quality planning all the way to supplier development and technical documentation. A wide range of checks and controls, as well as comprehensive quality assurance checks and tests, ensure that all defined quality requirements are observed.

Manufactured by PILLER – A quality promise

In recognition of the variety of tasks involved, our quality control (QC) is divided into two parts – an active part (QA) and a methodical part (QM). The chart below illustrates this distinction:

QC method (QM)

- Central standardization

- Documentation control

- Quality planning

- Central complaint management

– Coordination

– CIP measures - Supplier development/external inspections

- Technical documentation

– Directive 2014/68/EU

– Directive 2014/34/EU

QW test (QS)

- Incoming inspection

- Non-destructive test

– FE test (LEVEL II+III)

– MP test (LEVEL II)

– US test (LEVEL II+III)

– RT test (external)/Pressure test (AD 2000)

– Arcing test

– Bresle test

– PMI test (RFA and spectrometer)

– Salt test (contamination test)

– Cross-cut adhesion test of paint finishes

– Tear resistance test of paint finishes

– Hardness test - Outgoing inspection

Guaranteed blower performance

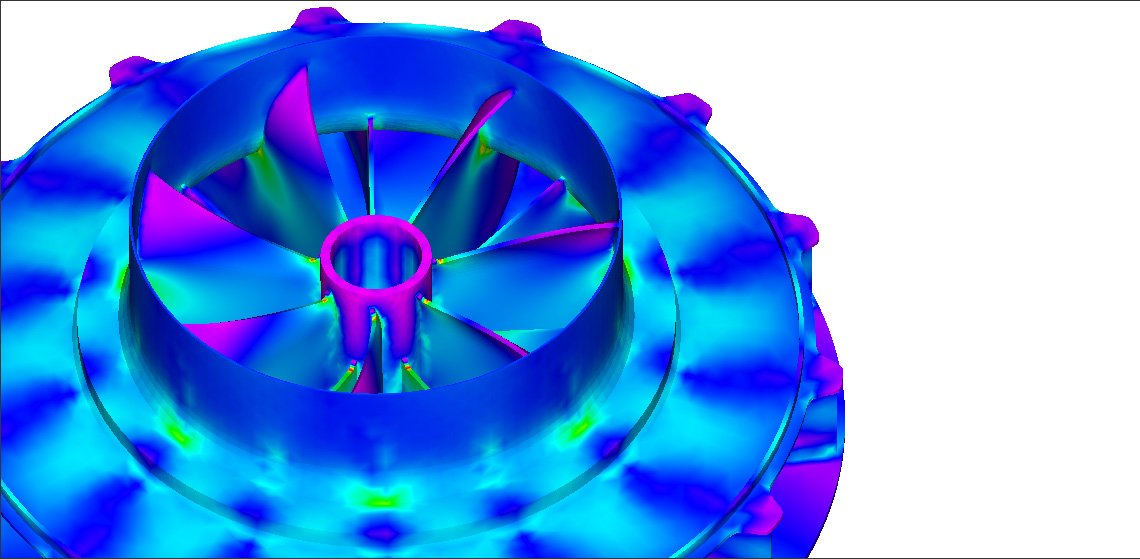

The name PILLER stands for the highest accuracy and compliance with all of our specified performance data. To ensure this, our R&D department uses the latest measurement, analysis and simulation technology.

Fan characteristics, vibration measurements: We guarantee the perfect performance of our blowers by using test setups that simulate the real operating conditions, and by data collection and processing using tailor-made software.

Our own testing field is equipped with all necessary measuring instruments and the latest technology, such as a special measuring carriage for data acquisition and transmission. Take advantage of our ability to simulate operating conditions on specially designed devices and test benches!

Trusted suppliers for best manufacturing results

Our high quality standards also require cooperation with highly efficient suppliers whose aim, like ours, is to continuously improve their procedures and processes to the benefit of the customer.

We therefore need suppliers who meet our requirements both economically and technically, and who are ready to embark on a process of continuous improvement with us. In selecting suppliers, we value quality, efficiency, delivery performance, reliability, service and environmental awareness.

Learn more about PILLER

Friday, 28. March 2025

Minister of Culture Hamburg visits PILLER in Moringen

Thursday, 27. March 2025

PILLER and GIG Karasek sign project contract for the world’s most powerful industrial heat pump system

Tuesday, 01. October 2024

We are a partner of the Blue Competence sustainability initiative of the VDMA

Contact

Piller Blowers & Compressors GmbH

Nienhagener Str. 6

37186 Moringen

Germany

![]() +49 5554 201-0

+49 5554 201-0![]() +49 5554 201-271

+49 5554 201-271