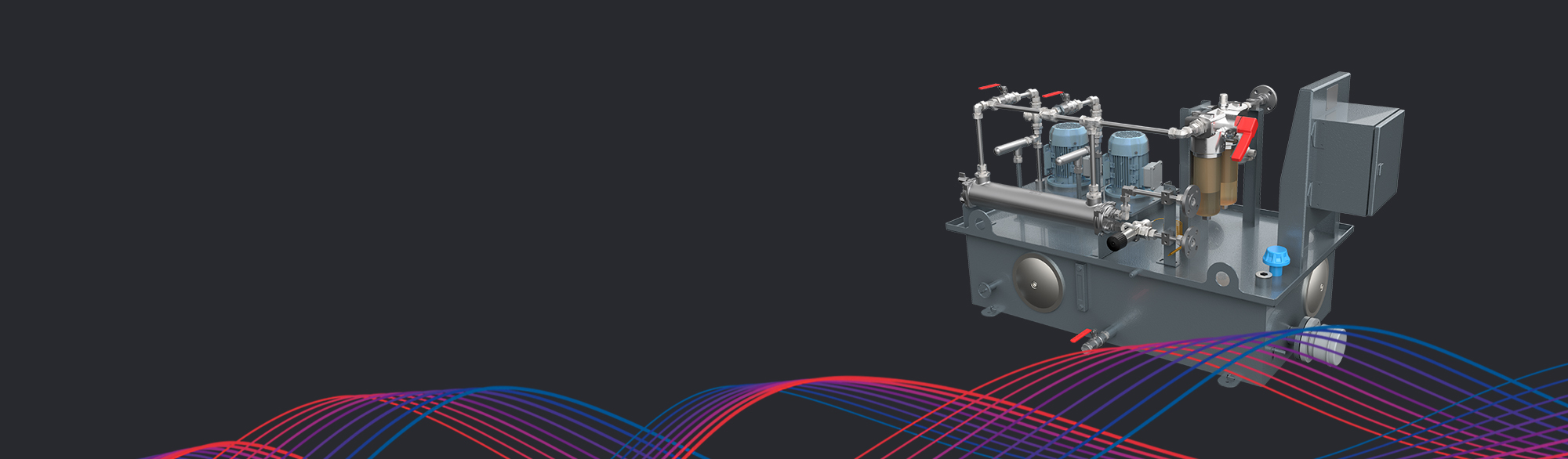

EASY OPERATION AND MODULAR DESIGN

Designed for the PILLER VapoMaxX

We have developed our oil supply system exclusively for the PILLER VapoMaxX. The result is a compact unit with flow panel that ensures maximum flexibility in design and installation, simple operation, and minimum downtime.

Our oil supply system is optimally designed for the PILLER VapoMaxX and is available in three variants: with a flow rate of 13, 33 and 45 liters/minute depending on the oil requirement of the supplied PILLER VapoMaxX machines.

It can be used for individual machines or as a central oil supply for several machines.

All variants are available with flange versions in ASME as well as DIN EN.

Maximum flexibility and reliability

Customized for the needs of our customers

The design of the oil supply system allows us to accommodate special structural features at our customers' sites and to install the oil supply system on other levels or in other rooms separate from our machine's location. In addition, we can meet process-related requirements with two different flow panel variants:

- flow panels can be mounted on the right or left side of the blower mount

- since the oil supply system has it's own terminal box, it can be mounted in a location separate from the machines

- the oil system can be used as a central oil supply for several machines, each connected by it's own flow panel, thereby increasing the flexibility of the design

- our standard flow panel ensures the supply of the gearbox and the machine bearing. The pressure and the flow rate for all lubrication points can be set and measured on the panel. As an option, the flow rate at each lubrication point can be measured, displayed, and communicated to the customer's machine control system

Reliable operation

Precisely integrated instrumentation

We have designed our oil supply system to provide high performance in a very compact design, relying on state-of-the-art equipment and instrumentation.

For our customers, this means:

- Shortened maintenance time and less down-time

- Minimized down-time - the redundant pump and filter system that can be transitioned during operation

- safe, year-round operation - the oil heater and cooler help ensure the necessary viscosities and thereby maintain the cooling ability of the lubricating oil

Shorter commissioning and maintenance time - our on-site service employees can easily and quickly set the oil pressure for all lubrication points and make changes to parameters directly on the machine at the flow panel in real time.

Learn more about PILLER

Friday, 28. March 2025

Minister of Culture Hamburg visits PILLER in Moringen

Thursday, 27. March 2025

PILLER and GIG Karasek sign project contract for the world’s most powerful industrial heat pump system

Tuesday, 01. October 2024

We are a partner of the Blue Competence sustainability initiative of the VDMA

Contact

Piller Blowers & Compressors GmbH

Nienhagener Str. 6

37186 Moringen

Germany

![]() +49 5554 201-0

+49 5554 201-0![]() +49 5554 201-271

+49 5554 201-271