ALWAYS ADVANCING

Learn everything you need to know about our VapoFan in our PILLER Webinar.

PILLER Webinars provide you with detailed information about possible applications, technical product features and maintenance instructions.

There are currently no planned dates for this webinar.

In the meantime we offer individual presentations for you and your team. Our experts will provide you with detailed information on our products and solutions and answer your questions.

Just send an e-mail to pbc-marketing@piller.de and schedule a meeting.

Dies ist ein Test

Dies ist ein Test

Dies ist ein Test

Dies ist ein Test

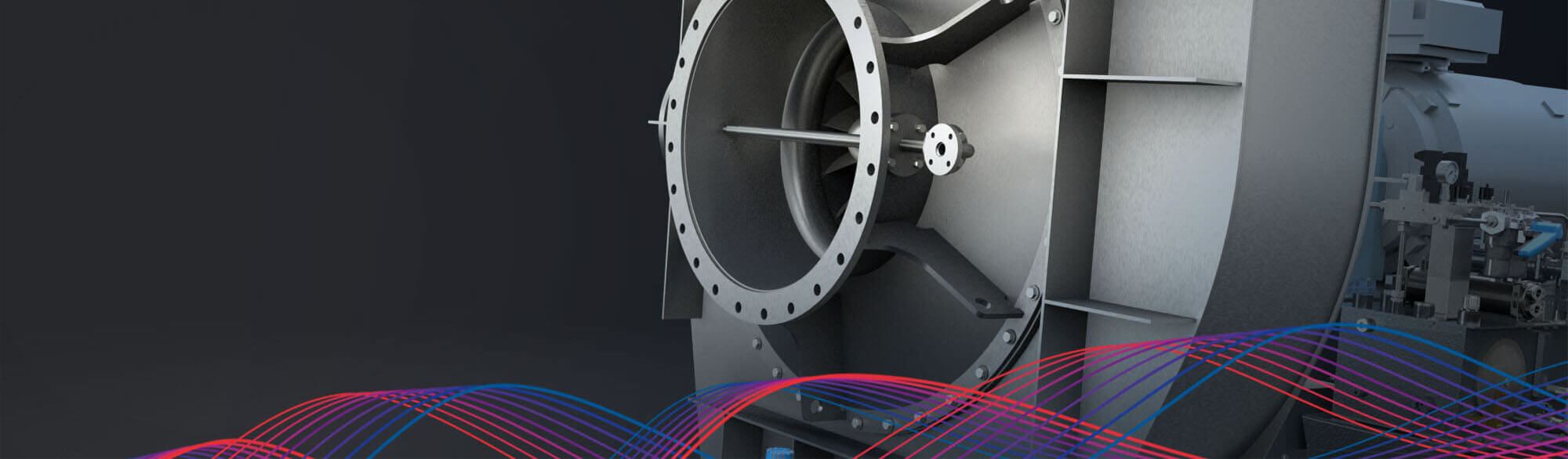

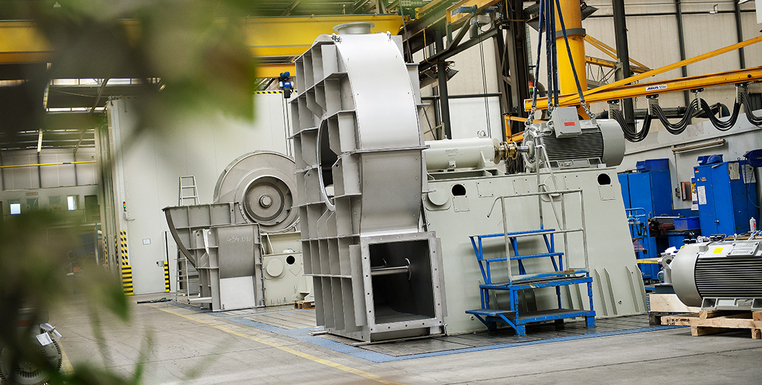

The VapoFan is ideally suited for integration into a compact evaporator system: with minimal space requirements, independent installation locations and optimal energy consumption.

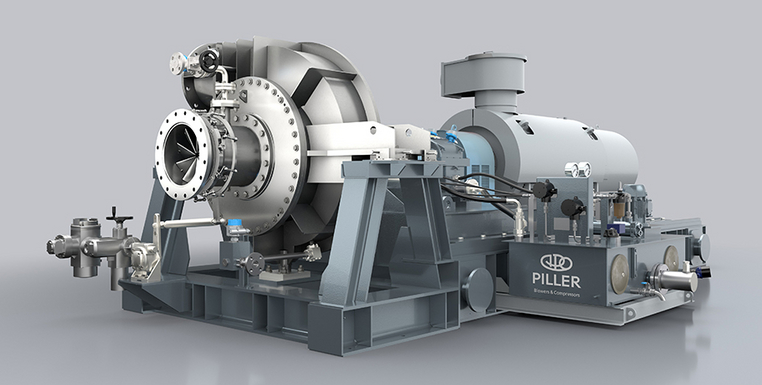

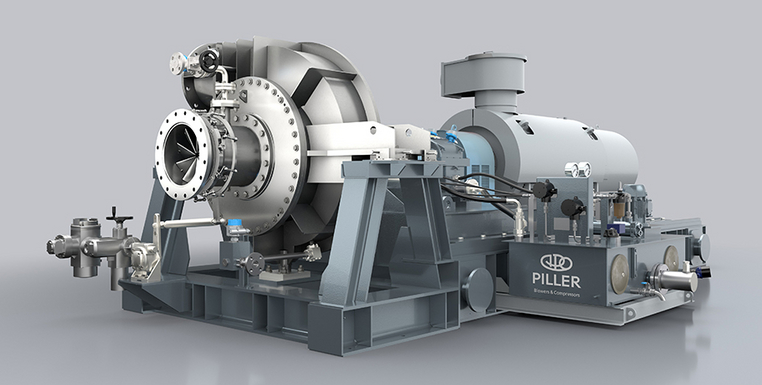

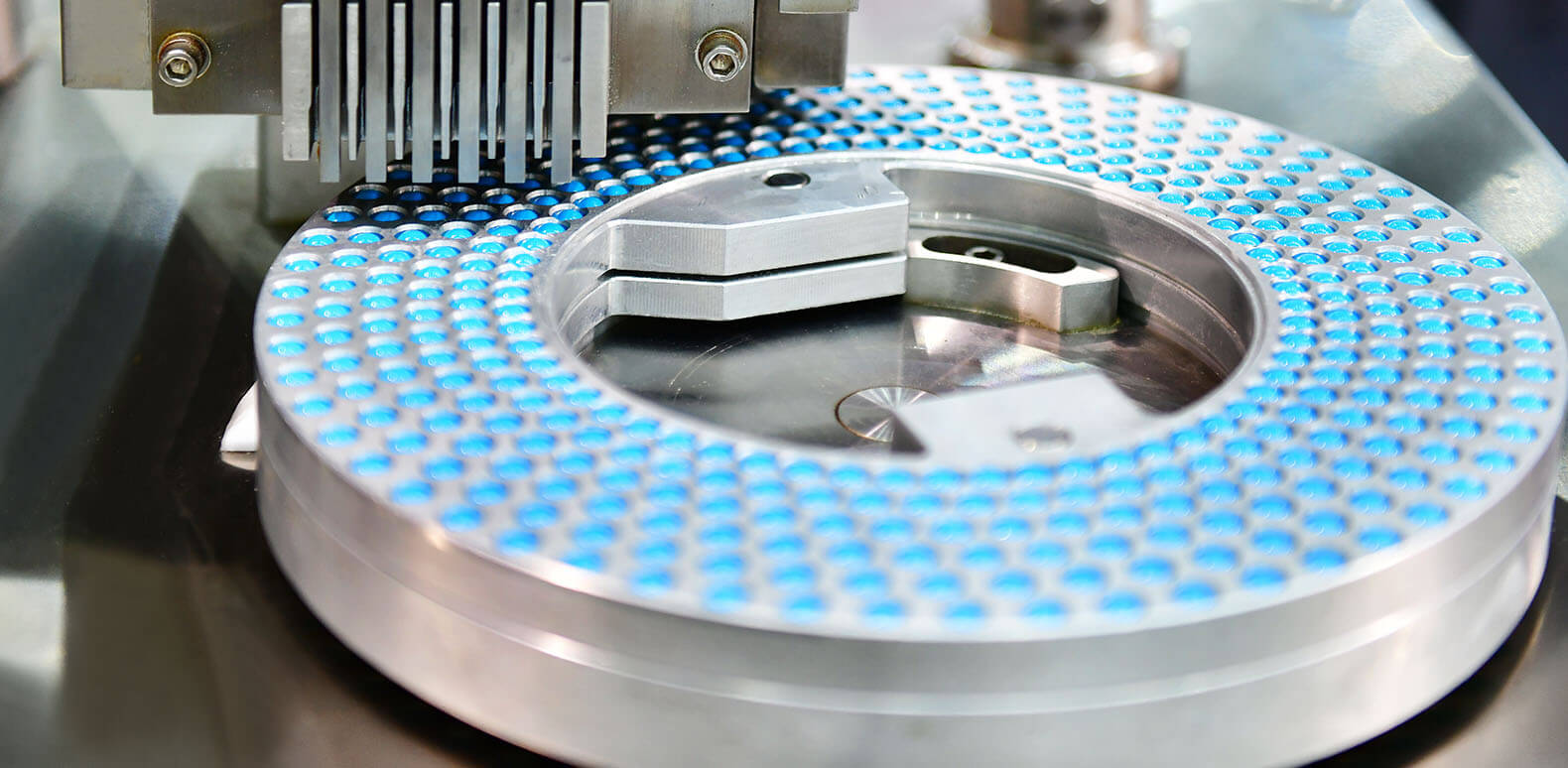

The perfectly harmonized drive unit is one of the reasons for the excellent efficiency. It consists of a synchronous motor specially developed by PILLER and a matching frequency converter in various capacities. A wide range of customer requirements can thus be covered and served.

The design of the VapoFan as a radial blower ensures reliable and smooth operation. The clearance dimensions between impeller and housing are sufficiently large to avoid any contact. Compared to rotary lobe blowers, PILLER VapoFans have an additional advantage: the flow is much more stable and the efficiencies remain constant within the wide operating range. The efficiency is up to 86% due to the ideal matching of motor and blower.

PILLER Webinars provide you with detailed information about possible applications, technical product features and maintenance instructions.

There are currently no planned dates for this webinar.

In the meantime we offer individual presentations for you and your team. Our experts will provide you with detailed information on our products and solutions and answer your questions.

Just send an e-mail to pbc-marketing@piller.de and schedule a meeting.

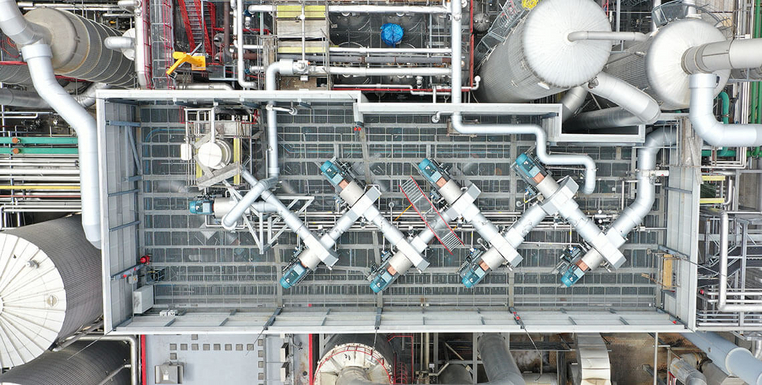

In the past, complex turbo compressors, with speeds of more than 12,000 rpm, or positive displacement blowers were used in the MVR process. Since the 1980s PILLER has provided powerful blower solutions for these applications.

Today, PILLER is the technology and market leader in the field of steam compression, using single or multi-stage high-performance blowers.

For good reason, PILLER counts among the international technology leaders for high-performance blowers and compressors.

Thanks to our experienced engineers and technicians, we offer process engineering expertise at the highest level. Our comprehensive service portfolio and our expert knowledge cover a wide range of applications, as well as individual, customer-specific solutions in almost every design.

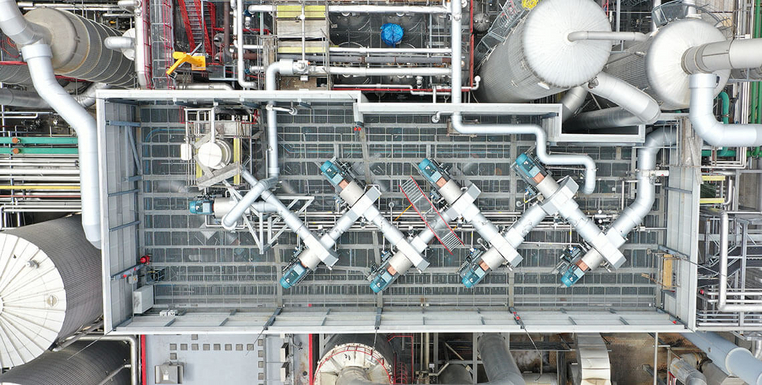

The top-quality products from PILLER are designed for various processes and the various sectors of the process industry.

Commissioning of a 6-stage VapoStation in Denmark

Minister of Culture Hamburg visits PILLER in Moringen

PILLER and GIG Karasek sign project contract for the world’s most powerful industrial heat pump system

We are a partner of the Blue Competence sustainability initiative of the VDMA

PILLER MVR Training in Scotland

Wednesday, 03. August 2022

Monday, 02. May 2022

Tuesday, 21. December 2021

Thursday, 21. October 2021

Thursday, 25. March 2021

Wednesday, 24. February 2021

Wednesday, 03. August 2022

Monday, 02. May 2022

Tuesday, 21. December 2021

Thursday, 21. October 2021

Thursday, 25. March 2021

Wednesday, 24. February 2021

Hier finden Sie sämtliche Informationen über aktuelle Veranstaltungen & Messen, Webinare, aktuelle Medieninformationen inkl. Bildmaterial.

Wir sind regelmäßig auf Messen in der ganzen Welt vertreten. Schauen Sie an unserem Stand vorbei.

Wir bieten regelmäßig Webinare zu unseren Lösungen an. Melden Sie sich an.

Hier können Sie sich über aktuelle Themen informieren. Schauen Sie doch mal rein.

News

Hier geht es zum Pressebereich. Hier finden Sie die aktuelle Berichtserstattung. Schauen Sie doch mal rein.

Pressebereich

Friday, 28. March 2025

Minister of Culture Hamburg visits PILLER in Moringen

Thursday, 27. March 2025

PILLER and GIG Karasek sign project contract for the world’s most powerful industrial heat pump system

Tuesday, 01. October 2024

We are a partner of the Blue Competence sustainability initiative of the VDMA

Piller Blowers & Compressors GmbH

Nienhagener Str. 6

37186 Moringen

Germany

![]() +49 5554 201-0

+49 5554 201-0![]() +49 5554 201-271

+49 5554 201-271