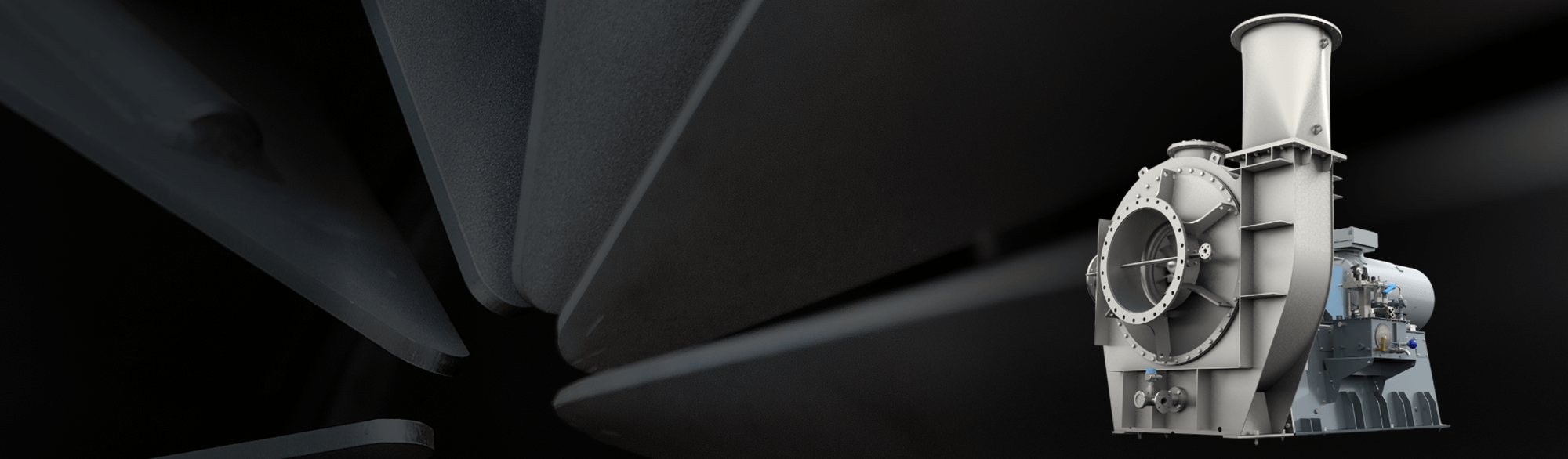

Customized MVR blower for your specific process conditions

Our VapoFlex concept is highly unique with 100% variability

Nearly limitless customization options in design and manufacturing: with the VapoFlex, a product of our VapoLine.

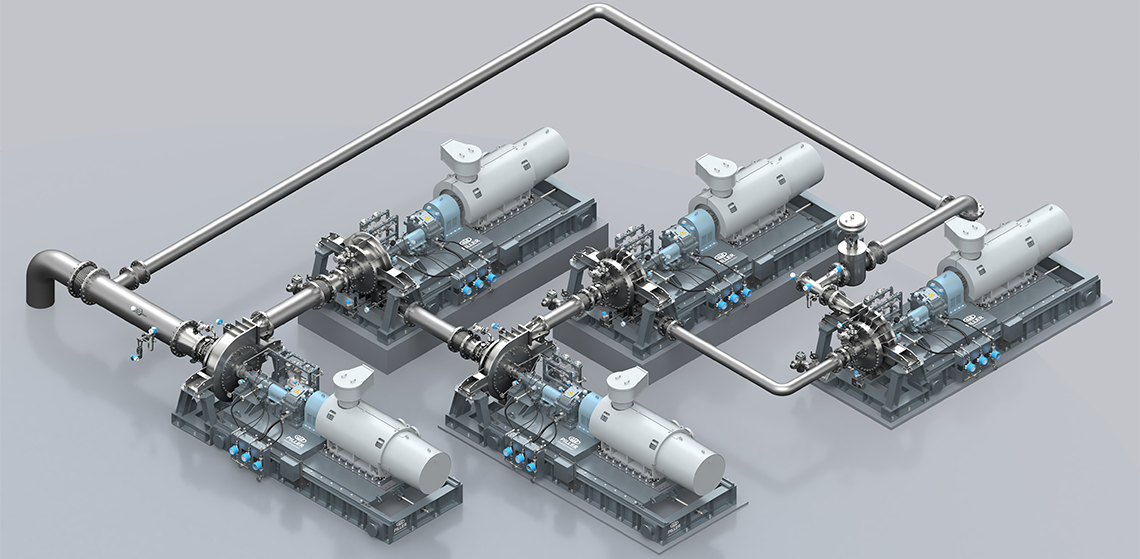

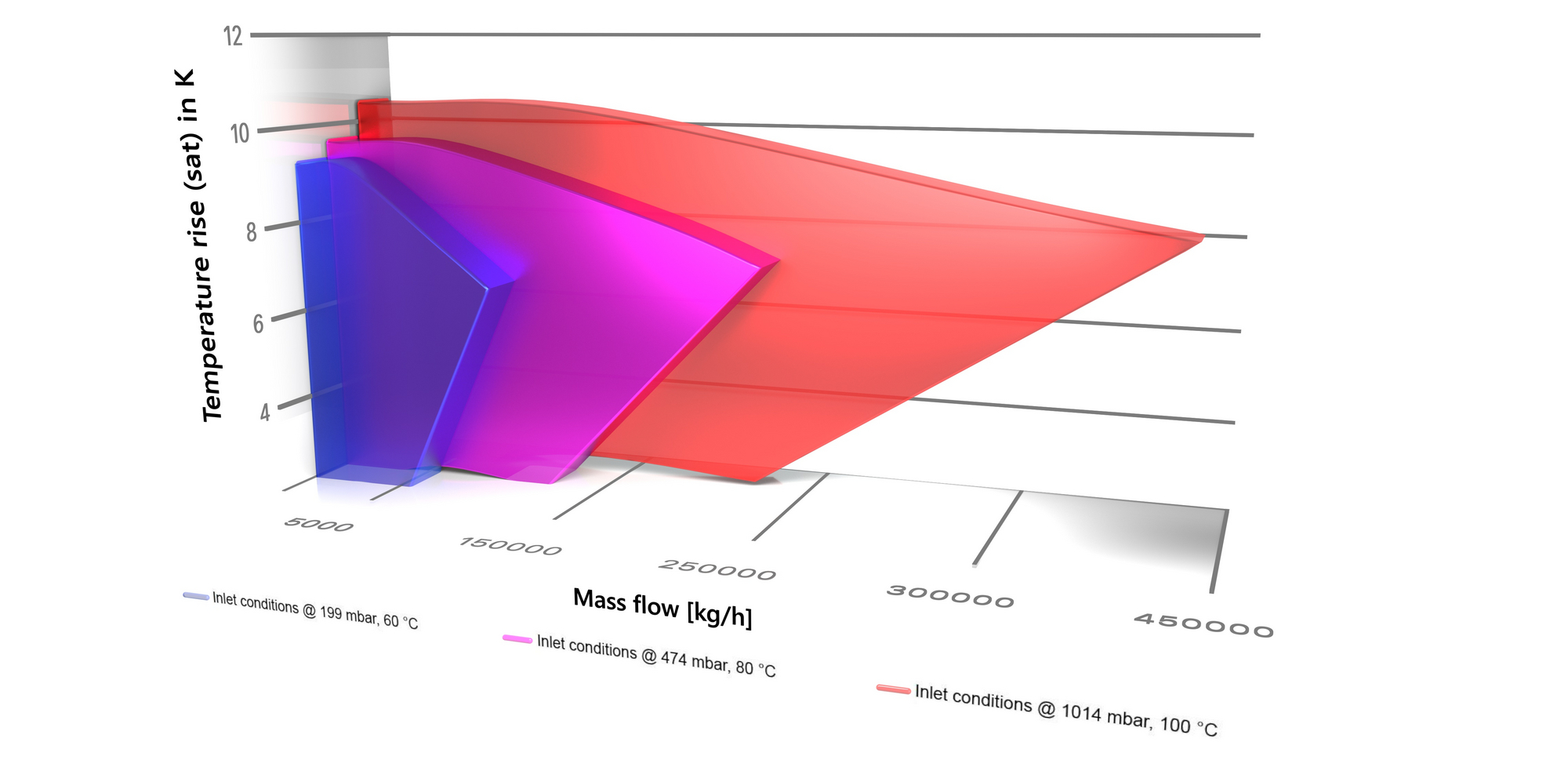

Due to various possibilities in terms of performance, PILLER's VapoFlex offers options in the mass flow range up to 250,000 kg/h with a temperature rise of 11 K per stage.

Advantages of our VapoFlex for Mechanical Vapor Recompression

PILLER MVR blowers guarantee smooth and reliable long-term operation, and its unique design is the key to significantly reduce the operating costs.

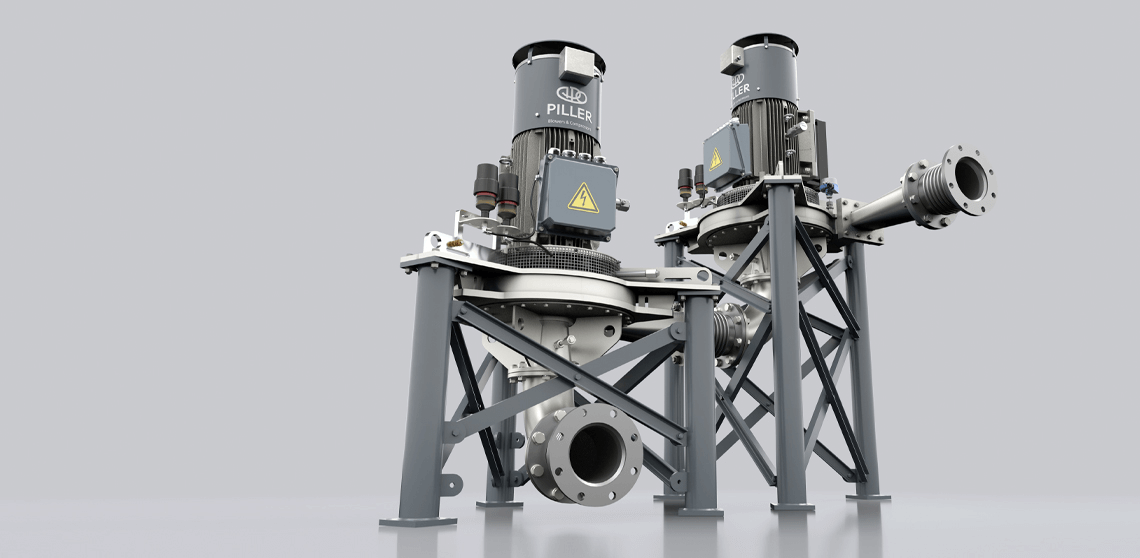

Through the variety of over 150 different high-efficiency impellers in single or serial connection, our VapoFlex's are a perfect match for any evaporation process and essential contributors for stability, efficiency, quality and cost-effectiveness of your process.

| Our VapoFlex at a glance: |

|---|

|

What means Engineered-to-Order?

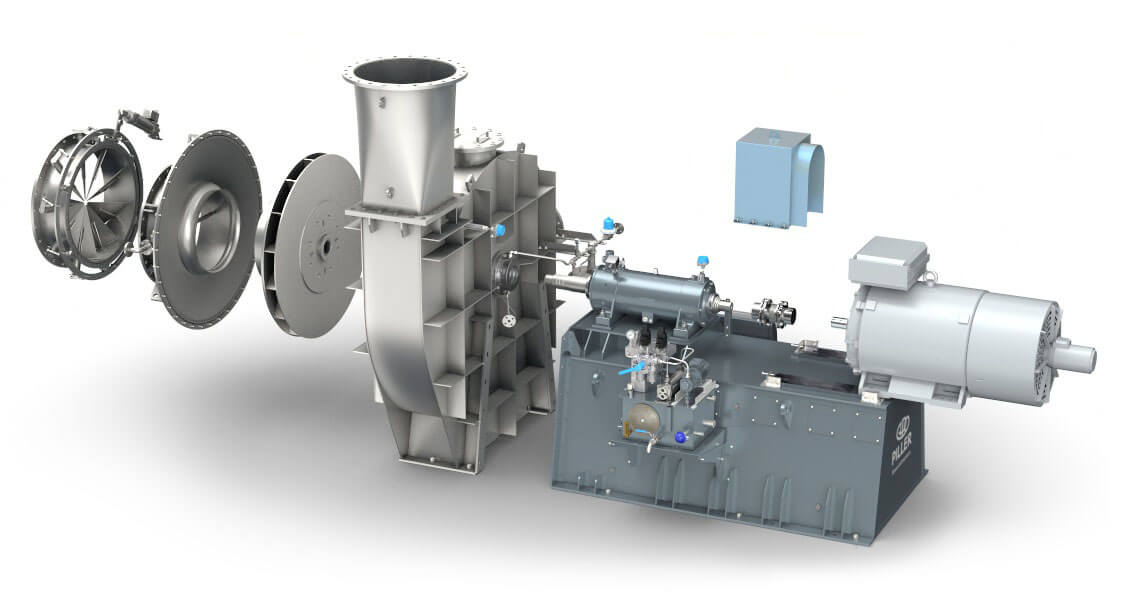

The VapoFlex solutions are perfectly designed and manufactured to suit a wide range of MVR applications. Finite Element Method (FEM) and Computational Fluid Dynamics (CFD) along with extensive empirical testing provide for continuous optimization of the performance and efficiency of our blowers – up to the performance limits of the individual selected materials. Every component is designed and selected to support performance and ease of assembly and maintenance.

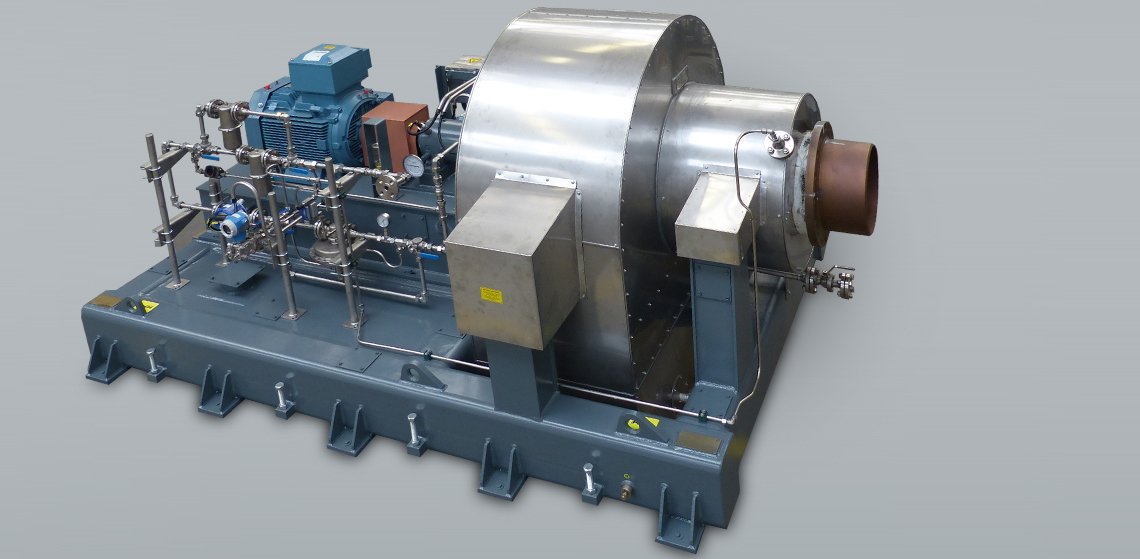

The drive concept

- Our patented squeeze oil bearing combines the simplicity of anti-friction bearings with the performance of hydrodynamic bearings

- VFD (Variable Frequency Drive) or D.O.L (Direct On Line, with inlet guide vane operation)

- Electric motors or steam turbines, according to customer specifications and technical requirements

- Motor capacity up to 6 MW

Key features of the PILLER VapoFlex

Performance summary of our VapoFlex product range

The widely used method of steam (Re-) compression is regarded as a reliable and effective measure for energy and CO2 savings by reducing steam consumption.

The VapoFlex are successfully used in many different applications, processes and industries:

- Distillation

- Crystallization

- High Concentration

- Zero Liquid Discharge (ZLD)

- Drying

- Wastewater reduction

- Water For Injection (WFI)

- Pulp and Paper

- Dairy industry

- Seawater desalination

Engineered for excellence

- Impeller geometries are optimized for the best possible aerodynamic load and efficiency

- Casing design for full vacuum up to 8 bar(g)

- Low-wear floating carbon ring labyrinth seals guarantee low shaft leakages

- Our patented squeeze oil bearing combines the mechanical simplicity and cost-effectiveness of anti-friction bearings with the performance of hydrodynamic bearings

- Water Injection on suction side for steam desuperheating and excellent cleaning effect for impeller

- Suitable for conditions in corrosive, abrasive or erosive environments

- Simple monitoring of critical operating conditions guarantees reliable performance

Find out more details on our high-quality blower components. All units, such as impeller, casing, motor, etc. and materials are precisely custom-selected according to your process, your product and your individual requirements.

More PILLER Products

Friday, 28. March 2025

Minister of Culture Hamburg visits PILLER in Moringen

Thursday, 27. March 2025

PILLER and GIG Karasek sign project contract for the world’s most powerful industrial heat pump system

Tuesday, 01. October 2024

We are a partner of the Blue Competence sustainability initiative of the VDMA

Contact

Piller Blowers & Compressors GmbH

Nienhagener Str. 6

37186 Moringen

Germany

![]() +49 5554 201-0

+49 5554 201-0![]() +49 5554 201-271

+49 5554 201-271